General Description:

Multifunctional tray type soft biscuit machine is new designed for biscuit forming into tray, the tray bake into rotary oven/rack oven, also it is can be connect to tunnel oven.

| The semi-automatic line is consist of: | |

| 1.Three roll Pre-sheeter | 2.Tray type rotary cutter |

| 3.Dough Recycling System | 4.Rotary Oven |

Data of the rotary moulder

1)Capacity:About 50kgs/hour~200kgs/hour

2)Working width 400mm.

3)Tray size: W400 x L600mm

4)Chain driver for dough feeding and moulding,more stronger.

5)Stainless steel 304#cover thickness 1.0mm

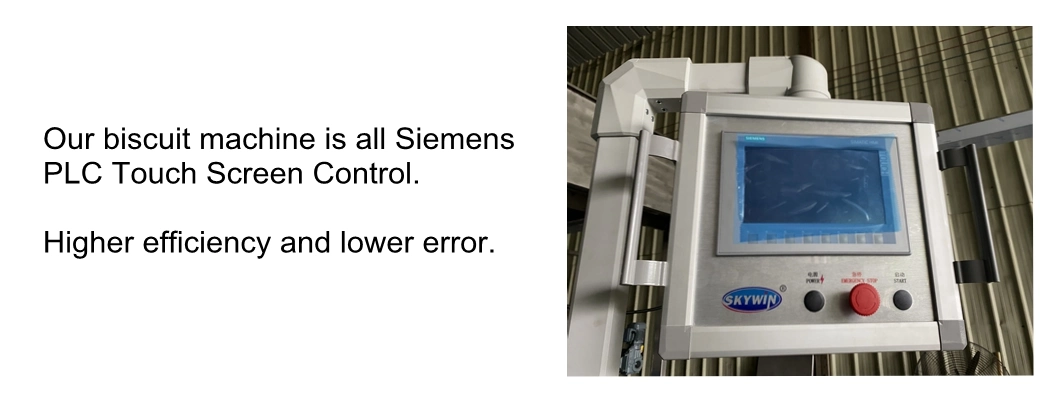

6)Frequency speed adjusted, Siemens or Schneider brand 7)PLC&Touch Screen.

8)Food standard Rubber roller diameter 200mm ,endless canvas conveyor.

9)Belts support by stainless steel 304# 3mm thickness.

10)With pan holding space and pan longer transport conveyor

11)With flexible waste dough collection pans, easier cleaning.

12)Tray delivery Max speed:16 trays

13)Max Automatic loading speed:10 trays

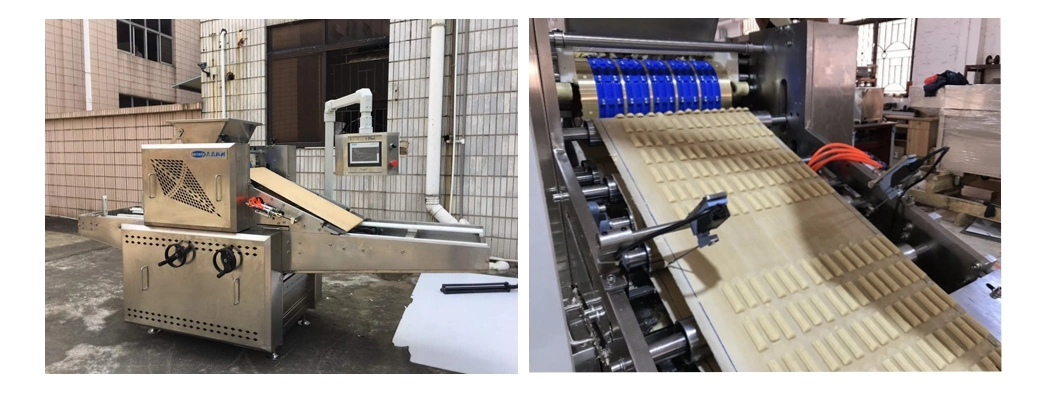

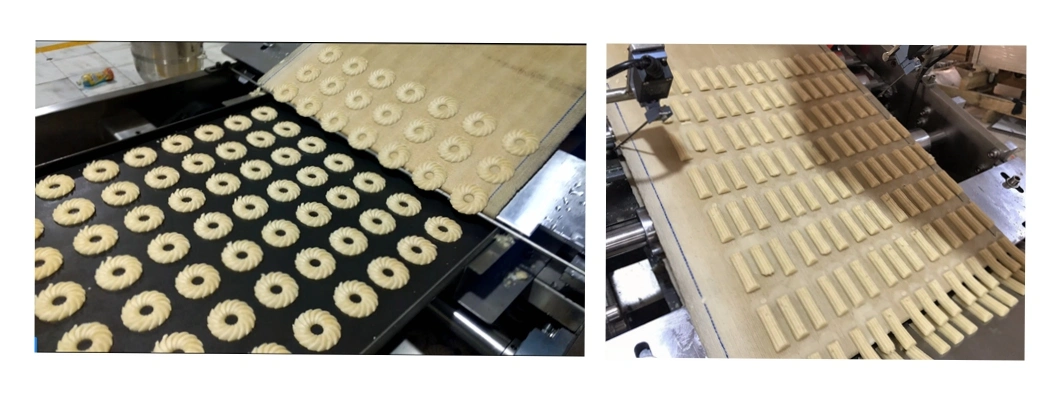

Detailed Images

Main features of the forming machine:

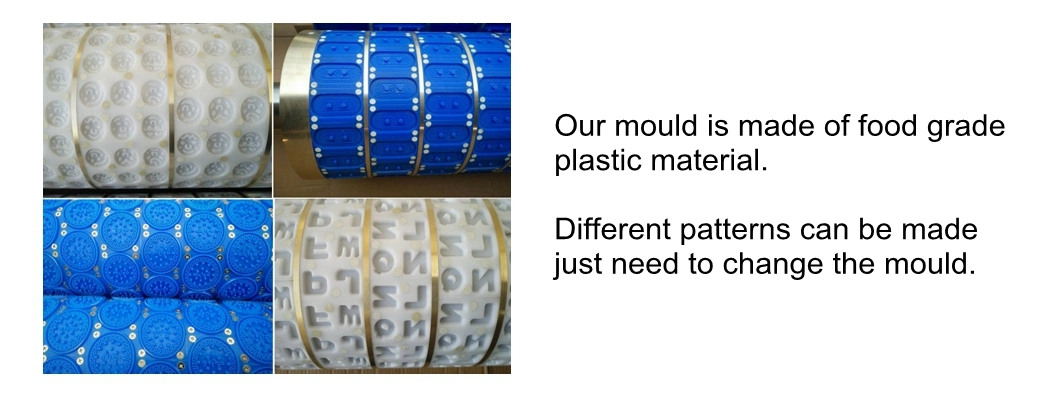

1. Flexible structure: with a series of quick-change biscuit molds device, can produce different shapes of biscuits.

2. With automatic loading and belt centering adjustment device. Ensure the automatic alignment of pallets and canvas;

3. Adopt 304 stainless steel, chromed plated treatment, to meet food hygiene requirements.

4. The machine is using frequency converters, Siemens brand PLC & touch screen control system,and other electrical components, mechanical stability and durability;

5. Machine control by Siemens Touch screen, easy to operate, no downtime at any speed will not be affected.

6. The machine is easy to clean and maintenance, waste collection pan for automatic collection of waste materials, avoid waste.

Machine is testing in the factory

About Us

SKYWIN Brand Multifunctional Biscuit machine is famous brand in China and oversea.

The advanced design from Europe and US. The senior engineers from European and US.

Our machines has sold to all of the world, the successful case included:

Egypt, South Africa, Nigeria, Zimbabwe, Mexico, Venezuela, Chile, Russia, Macedonia, Thailand, Malaysia, Saudi Arabia, Bangladesh, etc.

Packaging & Delivery

Our regular packagiing is multilayer packing, safe transport:

Step 1 : Mechanical surface coated with preservative solution ( to protect stainless steel).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement overall).

FAQ

Q1: Which kind of biscuit you can produce for your biscuit line?

A. Hard and Soft biscuit, Soda Cracker, Cookies, also Stick biscuit, Print biscuit and Chocolate filling biscuit, different shape biscuit just need to change the mould, we also can design mould for you as per your details.

Q2. What kind of oven you supply?

A. We can supply gas oven or electrical oven according to your requirement.

Q3. How long is your biscuit line?

A. we can design the biscuit line according to the layout of your workshop.

Q4. Which brand of motor you use for the line?

A. we can supply European motor reducer(SEW) or Chinese famous motor for your options.

Q5. Are you manufacturer?

A. Yes, we are a biscuit machine manufacturer in China.

Q6. How is the payment?

A. We accept 40% T/T deposit before production and 60% T/T balance before shipment,and Western Union or L/C.