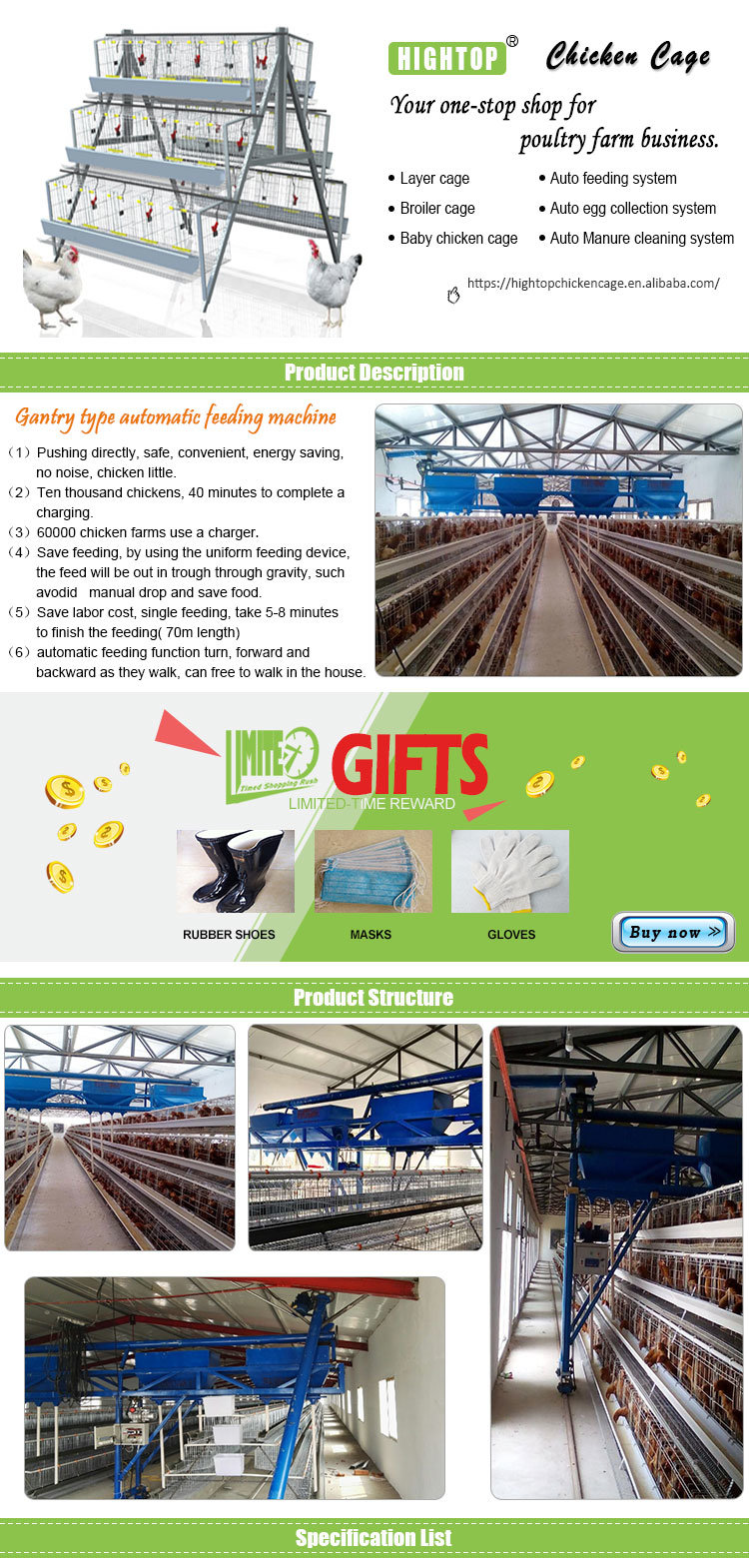

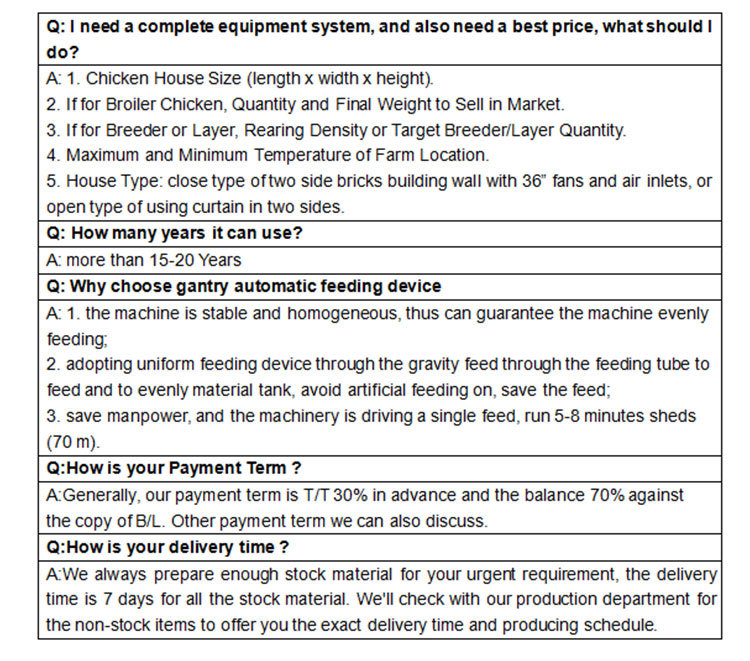

Automatic Layer Chicken Feeding Machine/Chicken Breeding System/Chicken Feeding Equipment

Repair and maintenance:

1. feeder at the time of running, it is best not to put the above things, then easy to cause the motor too

much stress and burn out.

2.check whether the belt is in good condition, whether there is loose.Feeder is to rely on the belt to transport

material, only the belt is normal to give full play of the performance of the machine, the work to achieve maximum.

3. because of the feeder are between the various parts of the gear and chain control connection, so you

have to make the gear and the chain to ensure the largest lubrication degree, such ability won't because

of the lack of lubrication and damage to the machine.

4. because of feed production will produce a lot of dust, will make the feeding machine control in the

accumulation of a lot of dust, dust can make the internal circuit short-circuit, damaged electric circuit

and other components, so every once in a while to clean up the dirt in the control box.

5. the feeding machine is the main power motor, motor power motor and gear motor (due to the

motor rotation speed is high, so use reduction motor to slow down at the transmit power).When using

a little should check the motor and gear motor to see if there is abnormal.Motor should be timely

maintenance, such as on reducer gear and gear oil etc.

6. Maintenance is a vital part of any operation, and so you must be aware of this especially in terms

of the reducer gear, gear oil and so on.

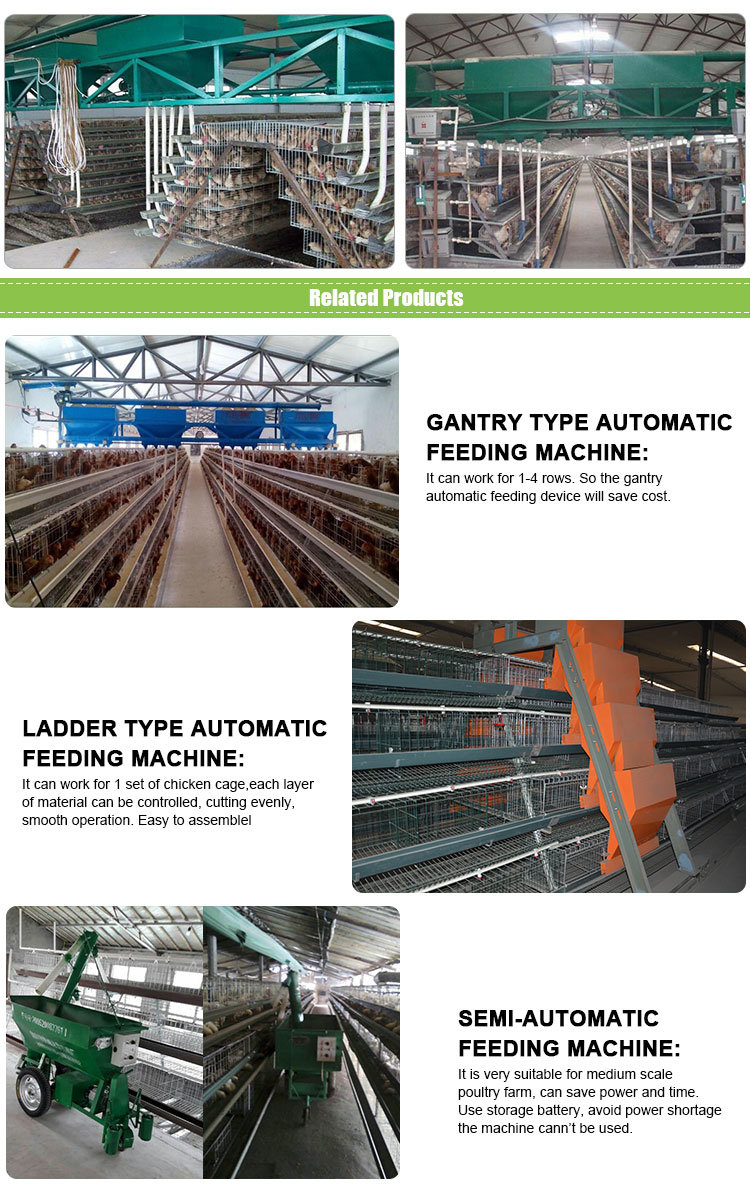

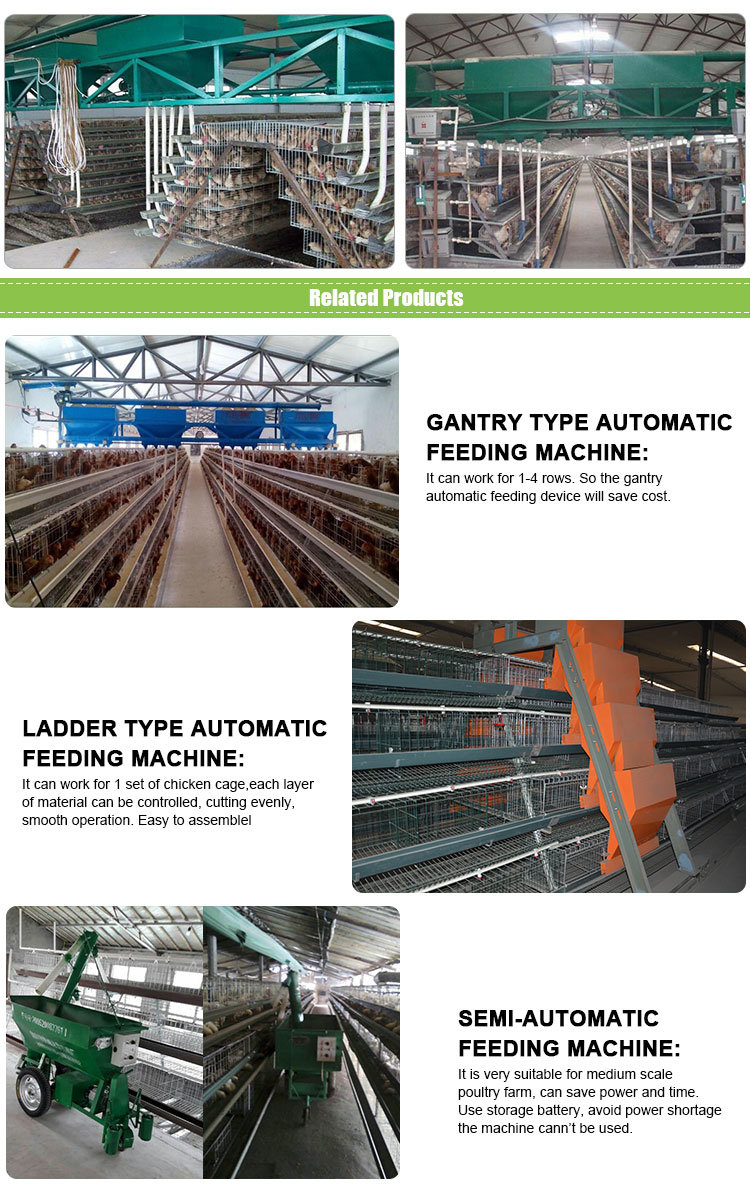

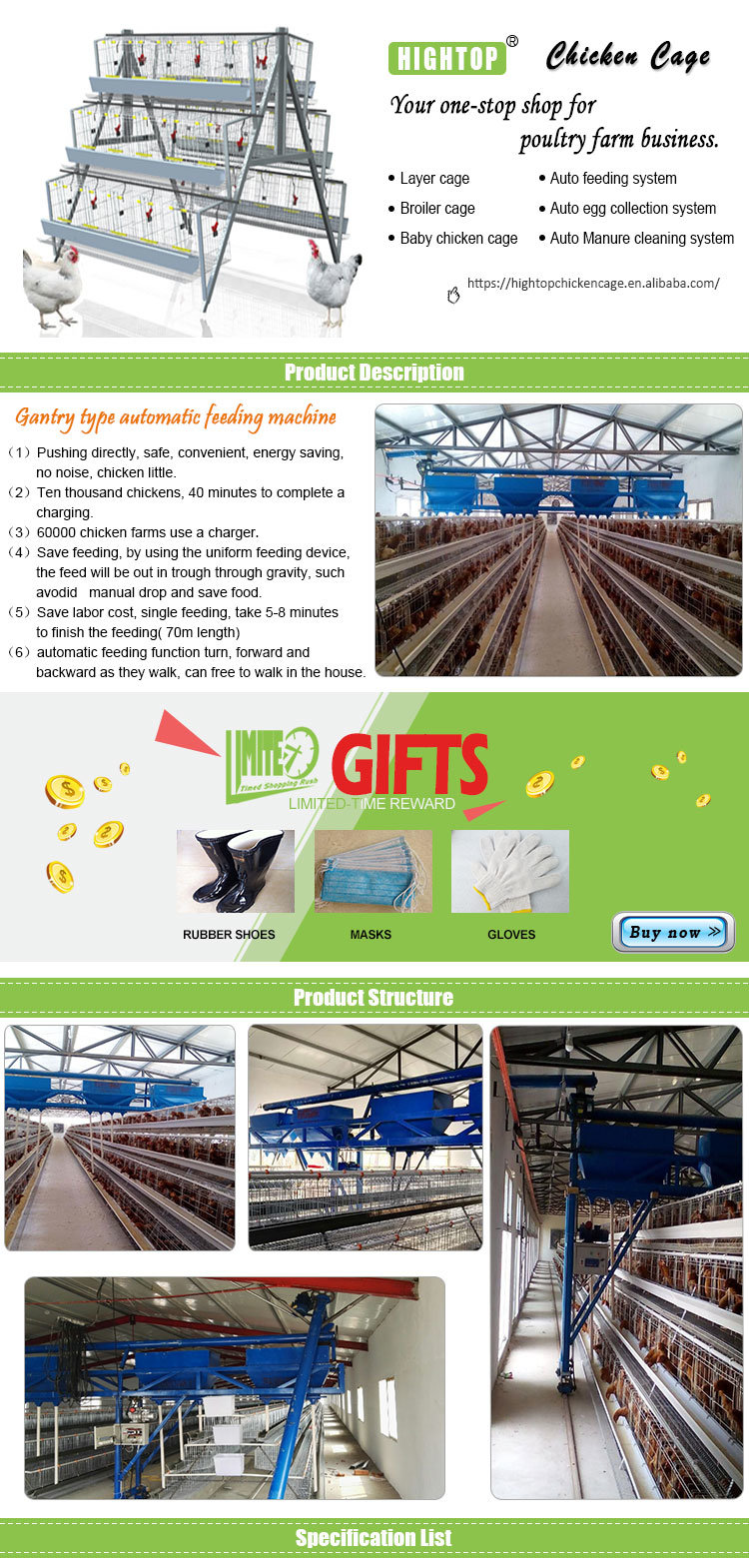

| Gantry automatic feeding machine | |

| Hopper material | 1 mm thick galvanized sheet |

| Running speed | 70 meters chicken house 5 - 8 minutes |

| Running distance | Hundreds of meters |

| Hopper capacity | 100 kg a bucket |

| Room height | Best in 3.5- 4 meters of above |

| other | Need to configure the ground screw conveyor to carry feed, diameter of of ground screw conveyor is 140 mm, capacity is more than a ton per hour. |

Repair and maintenance:

1. feeder at the time of running, it is best not to put the above things, then easy to cause the motor too

much stress and burn out.

2.check whether the belt is in good condition, whether there is loose.Feeder is to rely on the belt to transport

material, only the belt is normal to give full play of the performance of the machine, the work to achieve maximum.

3. because of the feeder are between the various parts of the gear and chain control connection, so you

have to make the gear and the chain to ensure the largest lubrication degree, such ability won't because

of the lack of lubrication and damage to the machine.

4. because of feed production will produce a lot of dust, will make the feeding machine control in the

accumulation of a lot of dust, dust can make the internal circuit short-circuit, damaged electric circuit

and other components, so every once in a while to clean up the dirt in the control box.

5. the feeding machine is the main power motor, motor power motor and gear motor (due to the

motor rotation speed is high, so use reduction motor to slow down at the transmit power).When using

a little should check the motor and gear motor to see if there is abnormal.Motor should be timely

maintenance, such as on reducer gear and gear oil etc.

6. Maintenance is a vital part of any operation, and so you must be aware of this especially in terms

of the reducer gear, gear oil and so on.